PPR pipe, also known as polypropylene random copolymer pipe, is a versatile and durable plastic piping system widely used in plumbing and heating applications. This article explores the composition, characteristics, uses, advantages, and environmental considerations of PPR pipes.

Composition and Characteristics

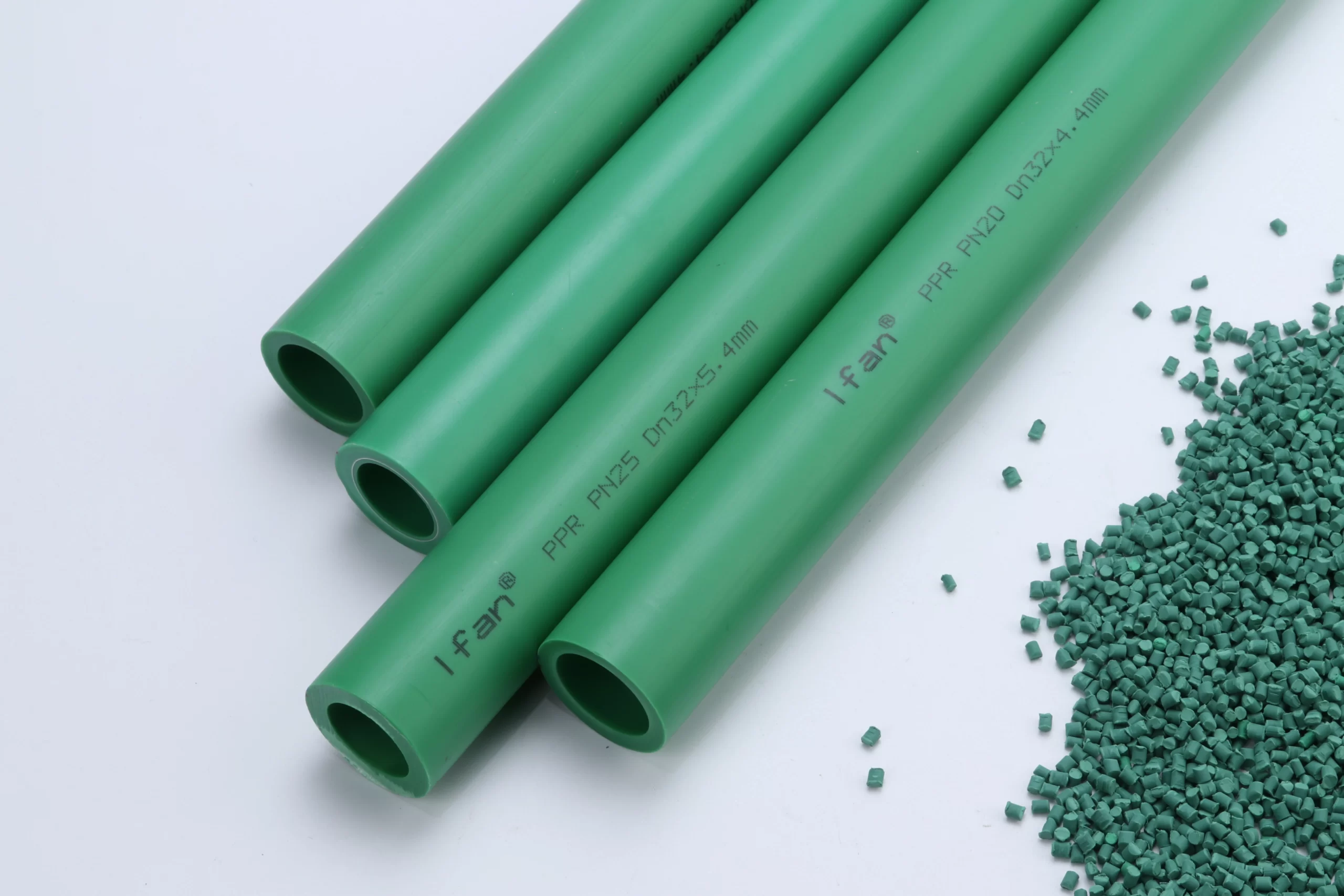

PPR pipes are manufactured from polypropylene random copolymer, a type of thermoplastic known for its excellent mechanical properties and chemical resistance. This material allows PPR pipes to withstand high temperatures and pressures, making them suitable for both hot and cold water distribution systems.

The manufacturing process involves extrusion and injection molding to ensure uniformity and consistency in the pipes’ dimensions and structure. PPR pipes are produced in standard lengths and diameters, facilitating ease of installation and compatibility with various plumbing and heating components.

Uses in Plumbing Systems

PPR pipes are widely used in plumbing systems for potable water supply due to their non-toxic nature. They do not leach harmful substances into the water, ensuring safe drinking water in residential, commercial, and industrial buildings. Their smooth inner surface prevents bacterial growth and scale buildup, maintaining water quality and flow efficiency.

In addition to cold water systems, PPR pipes are suitable for hot water distribution. They can withstand temperatures up to 95°C (203°F) without deformation or compromise in structural integrity. This thermal resistance makes PPR pipes ideal for applications such as underfloor heating, radiator connections, and other heating installations.

Advantages of PPR Pipes

PPR pipes offer several advantages over traditional piping materials. Their lightweight nature simplifies handling and reduces labor costs during installation. PPR pipes can be easily cut and joined using heat fusion welding techniques, creating seamless connections that are leak-proof and durable over time.

Durability is a hallmark of PPR pipes. With a lifespan exceeding 50 years when properly installed and maintained, they provide long-term reliability and cost-effectiveness despite their initial higher cost compared to some other materials. Their resistance to corrosion, chemical reactions, and abrasion further enhances their durability and performance in plumbing systems.

Environmental Considerations

From an environmental standpoint, PPR pipes are considered sustainable building materials. They are fully recyclable and contribute to reducing environmental impact throughout their lifecycle. Their durability and minimal maintenance requirements support sustainable construction practices by reducing waste generation and resource consumption.

PPR pipes also contribute to energy efficiency in buildings. Their excellent thermal insulation properties minimize heat loss in hot water systems, reducing energy consumption and operational costs over time. This enhances overall energy efficiency and sustainability in building projects.

Conclusion

In conclusion, PPR pipes represent a modern and efficient solution for plumbing and heating systems. Their composition from polypropylene random copolymer provides superior mechanical strength, thermal stability, and chemical resistance, making them suitable for diverse applications in residential, commercial, and industrial buildings.

PPR pipes excel in ensuring safe water supply and efficient hot water distribution, contributing to energy savings and operational efficiency in buildings. Their ease of installation, longevity, and environmental benefits make them a preferred choice for sustainable construction projects aiming to achieve reliable performance and durability.

As construction practices continue to evolve towards sustainability and efficiency, PPR pipes remain at the forefront, meeting the demand for innovative piping solutions that combine reliability, safety, and environmental responsibility in the built environment.